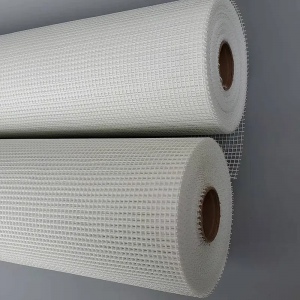

As this innovative material continues to make waves across industries, the future of fiberglass alkali-resistant mesh is very bright. The mesh is composed of C-glass or E-glass yarns and is coated with an alkali-resistant polymer emulsion, which has several advantageous properties, including high tensile strength and excellent resistance to alkaline substances. It is therefore not surprising that it is widely used as a reinforcing material in wall EIFS, cement products and the backsides of granite, mosaic and marble. It is widely used for waterproofing asphalt roofs, among other applications.

One of the key drivers behind the growing popularity of fiberglass mesh is its impressive tensile strength. This property allows it to effectively strengthen structures, providing enhanced stability and durability. Its ability to withstand the forces and stresses found in a variety of applications ensures structural integrity and longevity, making it the first choice for many construction and manufacturing projects.

Additionally, the mesh’s alkali-resistant properties further add to its appeal. It has excellent resistance to alkaline substances such as cement and other alkaline materials found in construction applications. This resistance prevents degradation and deterioration of the mesh, ensuring its integrity and performance. It therefore provides reliable reinforcement and protection against the damaging effects of alkalis, increasing its demand in industries that are frequently exposed to such elements.

Additionally, the versatility of fiberglass alkali-resistant mesh makes it suitable for a wide range of applications. Its compatibility with different materials such as cement, granite, mosaic and marble allows it to be seamlessly integrated into a variety of construction and manufacturing processes. This flexibility and adaptability contributes to its widespread use in multiple fields.

Furthermore, the demand for such grids is expected to surge due to the growing construction industry across the globe. As urbanization continues to grow at a rapid pace, there is an increasing need for strong and durable structures. The use of fiberglass alkali-resistant mesh helps meet these requirements, providing enhanced reinforcement capabilities for cement products and wall exterior insulation systems alike.

In summary, the development prospects of fiberglass alkali-resistant mesh cloth are very optimistic. Its excellent tensile strength, alkali resistance, and compatibility with a variety of materials make it an important reinforcement material in construction and manufacturing. As the demand for strong and reliable structures continues to grow, this grid will undoubtedly play a key role in meeting industry needs. With its diverse applications and potential in the global market, fiberglass alkali-resistant mesh is set to flourish in the coming years, revolutionizing the way construction and manufacturing projects are reinforced and protected.

We always have our own company vision. With our healthy and environmental protection materials, build a harmonious living environment, so that our earth is always full of green and infinite vitality. Adhering to this company vison, we have strictly produced the company's products. We also produce fiberglass alkaline resistant mesh, if you are interested in our company and our products, you can contact us.

Post time: Oct-10-2023